Quality

Safe, reliable products

So you can use Nature’s Way products with safety and peace of mind, we aim to produce safe, reliable products through thoroughly checking safety in all processes from selection of raw materials through R&D, production, distribution management, and after sales.

Nature’s Way’s pursuit of safe, reliable products

Nature’s Way strives to improve product quality and safety through the processes of R&D, plant production, logistics, and after sales

-

- Step1R&D

- Selection of raw materials

Compounding

Scale-up testing

-

- Step2Plants

- Acceptance of raw materials

Sanitation management in production processes

Quality control in production processes

-

- Step3Logistics

- Production management in distribution

-

- Step4After sales

- Customer contact center

Quality assurance, safety management

Research and development

Based on the principles of delivering health benefits, safety, and lower environmental impact, Nature’s Way products are developed with care from selection of raw materials through production.

Selection of raw materials

We select raw materials with an emphasis on natural sources such as plant-based oils and extracts and essential oils. To put the power of plants to effective use, we strive to incorporate them into our cosmetics products in as natural a state as possible.

To use plant-based extracts as an example, these ingredients consist of exquisite blends of dozens of natural ingredients, which do not always maintain the same state. They can be used in cosmetics only through carefully ascertaining their state and processing them appropriately.

Giving top priority to customers’ safety and peace of mind, we use ingredients that do not stress the skin. We have established our own Nature’s Way ingredient standards under which we research and develop products using formulas that can maintain quality without use of paraben, tar pigments, silicone, mineral oil, or ultraviolet absorbents.

Since naturally sourced materials are vulnerable to the effects of the air, in selection of containers as well we strive to choose ones that will protect our products from contact with the air, through means such as use of backflow check valves

Compounding

Cosmetics are compounds of a wide range of raw materials. Prototypes are designed to balance properties such as their feel on the skin and their benefits.

We also emphasize product quality and safety. We test prototypes for stability under severe conditions of extreme heat and cold. Only those that satisfy certain standards can proceed to the final product stage.

Preservation testing is essential to product quality and safety. We assess prototypes for safety with regard to not only general bacteria but also clinical isolates in the plant that possibly could infect them.

We conduct monitor evaluation testing of prototypes that have cleared these quality tests, and those recognized to have safety and skin benefits are chosen as final product formulas.

We do not use animal testing to check product safety

Scale-up testing

After a prototype formula* has been decided on, production testing takes place using plant machinery. Like formulation prototypes, scale-up prototypes produced in production testing are subjected to stability testing and preservation testing. It is difficult to produce scale-up prototypes with the same quality as formulation prototypes. Sometimes, even though at first glance a scale-up prototype may seem to match the formulation prototype, it may deviate in terms such as stability and preservation. We optimize conditions such as machinery RPMs and mixing time, to establish manufacturing methods capable of maintaining the same level of quality at all times.

Testing in actual use is conducted using scale-up prototypes that have passed stability and preservation testing, checking for any issues in ease of use. In this way, we strive to secure quality through testing based on the customer’s point of view.

* Prototype formula: The formula of the prototype before final product development

Plant

At our plant, we control quality in accordance with cosmetics good manufacturing practice (GMP) standards, ensuring that quality conforms to design specifications at all times

Acceptance of raw materials

We strictly check the materials and supplies used in producing our products, to eliminate any abnormalities. It is said to be difficult to realize consistent quality when using natural ingredients, since their colors, fragrances, and other properties may vary with their locations and conditions of production. We manage raw materials properly by specifying materials standards and best-by dates. We check printed materials such as product containers and boxes in advance to ensure that they include all labeling of ingredients and other information required by law. Then, we check for any printing errors or failure to satisfy standards in areas such as color density.

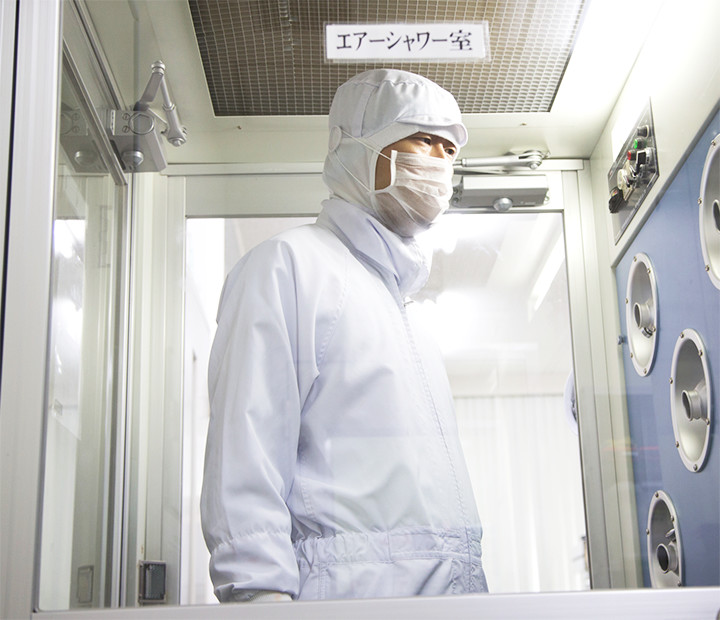

Sanitation management in production processes

The plant is separated into three areas by necessary sanitation level. In the clean room, where cosmetic ingredients are compounded and filled, we manage sanitary conditions through regular measurement of floating dust particles and other impurities. We maintain a 10,000-class purity level—the same level used in production of pharmaceuticals.

We also employ various measures such as regulating air pressure inside and outside work areas, to keep out insects from the exterior.

Quality control in production processes

In each production process, we check samples of all products to ensure that they satisfy standards. Generally, we conduct testing once at the stage at which the fluid ingredients are complete, and if the product passes this test then it proceeds to the filling process. Final testing is conducted after filling and packing, and only products that pass this testing are shipped.

Logistics

Product management in the distribution process

To maintain the quality of our carefully made products, we store them in warehouses subjected to steady temperature control. Like our plant, our warehouses too are separated into individual areas by degree of purity, and we maintain a structure to keep out impurities.

After sales

Customer contact center, quality assurance, safety management

After product sales, we collect a wide range of feedback from customers. Valuable customer feedback is very important to us, and it serves as a source of information for new product development and continual quality improvements. For particularly urgent cases, we maintain a structure to enable immediate notification of the President and related sections and responding swiftly